After about a month or two of work, I've finally completed my first basic Combat Robot! I had a lot of help on the design from Brandon, our Mechanical Engineer Lead at TCCR. He's been doing this for an impressive 14 years!!

(My robot, the AllenBot.)

The design work was done in OnShape, an open-source, cloud/browser-based, CAD software (Compatibility with Linux is the main reason I chose to use it). I spent a few months with the club learning the basics of the program and general design of a Combat Bot. The electronics are simple enough. It's a lot like a like a standard RC-Car, on steroids... This tutorial will be over building a basic 1lb Plastic AntWeight (PLANT), Vertical Spinner: https://battlebots.fandom.com/wiki/Vertical_Spinners

Most of our club's parts are sourced from RepeatRobotics.

I started out by setting my electronics on a table and sketching out a design around them on paper:

Once I had an idea of how I needed to fit the components, I started modeling!! We start out with a box shape, and start slowly shaping out an edge on the front.

When shaping out your robot, there's a few goals you want to keep in mind:

After that, it's a matter of shaping out spots for your parts. A huge help in doing this is using GrabCad, a website that allows you to search for components and get measurements for them, or even download a model to shape your parts around. For example, this is the dimensions for the wheel's motor: https://grabcad.com/library/repeat-max-brushed-1

As you shape out your bot, you'll have something like this:

It'll be good to print that out as is, so you can physically start putting your electronics in for fitting. As you build around your parts more and more, you'll start to see something like this:

The weapon rails are the next part I worked on. These are the pieces that hold the weapon and motor in place. We use Brushless Motors, the same kind that Drones use for flight: https://grabcad.com/library/repeat-ant-2822-1

There isn't too much to say about the weapon rails. You'll follow the same idea, and design around component you will be using. Measuring each section, and really going crazy with the fillet/Chamfer tool. The only important things I would note is to add 3 screw holes to it for mounting, and adding a hole on the side to lock your weapon in place.

The weapon is probably the more 'intricate' piece in the design. It's important to focus on three things:

Go ahead and first create a circle, extrude it, and add a hole in the center for your weapon to fit in.

Next, we'll Right-Click the part, and select 'Assign material...'. Type in the material you plan on printing your part with, and press the check mark when done (We use PLA commonly).

You can now select your weapon and click the 'Display Mass' tool on the bottom right. It will then bring up this screen, and will show a new pointer on the screen. This is how you detect the center mass of your weapon. As you change the shape of your weapon to add edges and curves, you'll notice the pointer change locations. This shows your weapons weight distribution and how off-center it is or isn't.

When you model out an edge for your weapon to attack with, you'll want to increase the mass on it's opposite end as a counter-balance.

Ideally, you want your center-mass pointer as close to the center as possible.

Don't forget to model out your weapon lock holes within the weapon...

After all this, and confirming the weapon fits in your Assembly view (Give it about 4mm clearance from the Weapon Rails), you are done! Print out your parts, check if they fit, and update as needed!

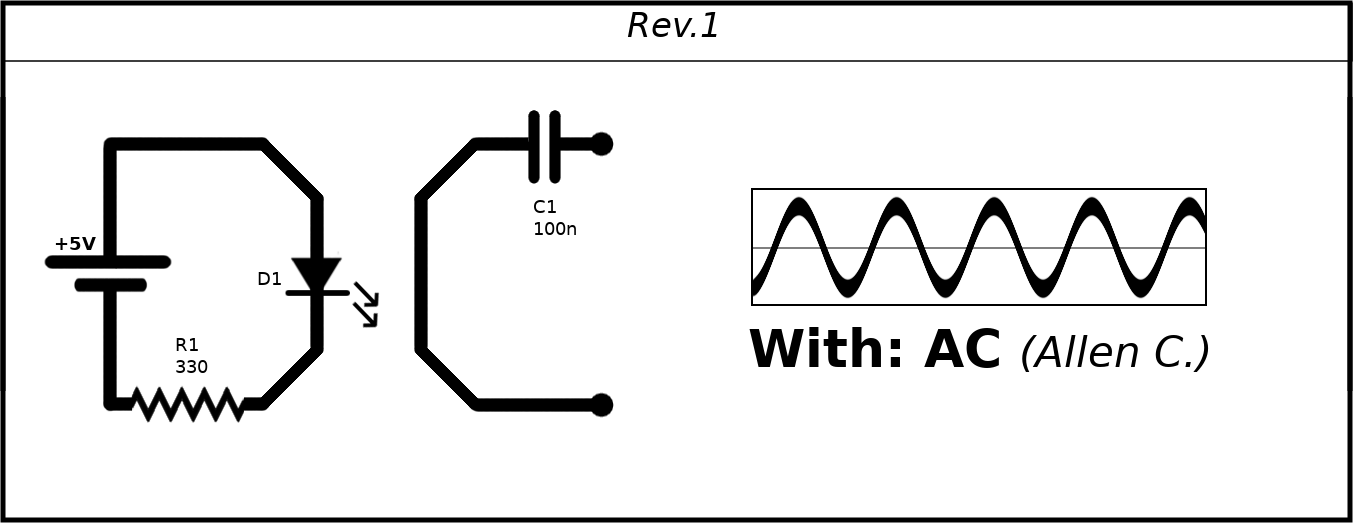

This will be the fun part (atleast for me lol). Collect your components, and start connecting/soldering wires! I'll provide a schematic and picture of my components connected. You'll just be following along:

The trickiest part of this is fitting your electronics inside your case. I had to splice wires together to stretch connections into different areas of the robot.

This concludes the tutorial for building a Plastic AntWeight 1lb Vertical Spinner. The only thing left to do is make a lid to cover your circuits test your new bot! Always make sure to operate with safety in mind. We follow SPARC guidelines, and I recommend other's read it for general Combat Robot operation safety: https://sparc.tools/SPARC_Robot_Construction_Specifications_v1.4.pdf

It's been hard to squeeze in time to work on a robot while also managing my club's AV/Social Media and going to school, but I managed to get it done and I feel very proud! There are a few things I would do differently in the future, for example, I made the Weapon Rails on my robot too thick. Because of that the weapon can grind and get stuck on them. There's also print settings I can optimize for a stronger print that I originally didn't know about, such as slowing the printing speed for stronger adhesion. I'll be using what I learned for future projects and i'm very grateful to have had this opportunity!

-Thanks for reading, Allen.